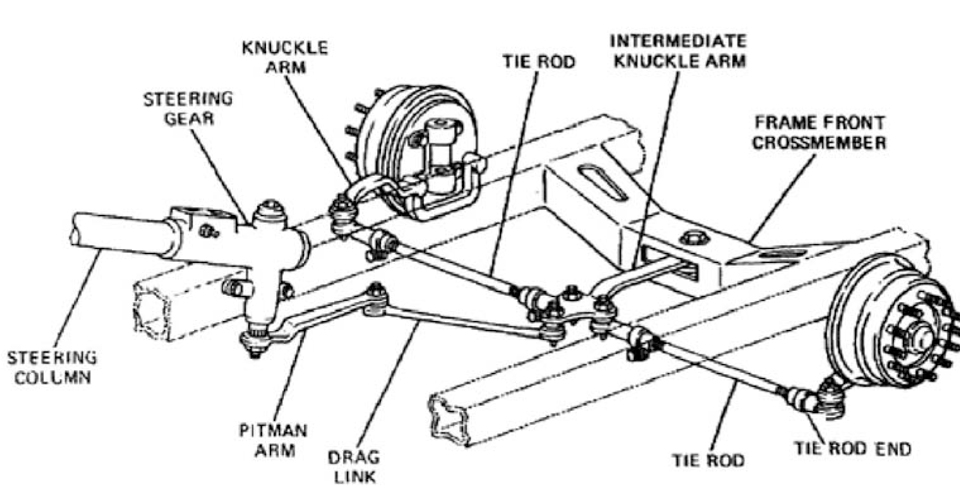

Tie-rods are a key part of this system, and are responsible for transmitting the forces you input through the steering wheel to the front wheels, allowing you to change vehicle directions. A tie-rod connects, or “ties,” the front wheels of the vehicle together so they both turn from left to right at the same time. One side connects to the steering knuckle, while the other side either directly connects to the steering gear or is attached with other linkages. The tie-rod assembly often is made up of an inner and outer tie-rod, which are joined by an adjusting sleeve. The sleeve allows for the length of the tie-rod assembly to be changed when necessary for correct wheel alignment.

Complete tie-rod failure can be catastrophic, resulting in the complete loss of steering control. Most of the time, failure is gradual, with the tie-rods exhibiting movement in the tie-rod ends, or the flexible socket that allows for movement and pivoting while steering. The movement grows progressively worse, until the tie-rod end separates. This separation can be sudden and brought on by impact with a road hazard such as a pothole or curb. As the tie-rod becomes worse, wheel alignment changes, and your vehicle exhibits increased tire wear or strange tire wear patterns. Erratic vehicle handling, shaking or vibration while driving also may be present.

Have your vehicle’s steering and suspension inspected on a regular basis to ensure the tie-rod assemblies are tight. If the tie-rod ends are equipped with grease fittings, make sure they are greased at every service. Do not fill the tie-rods with so much grease that the boots protecting the connection break, as this can allow contamination that leads to premature failure.